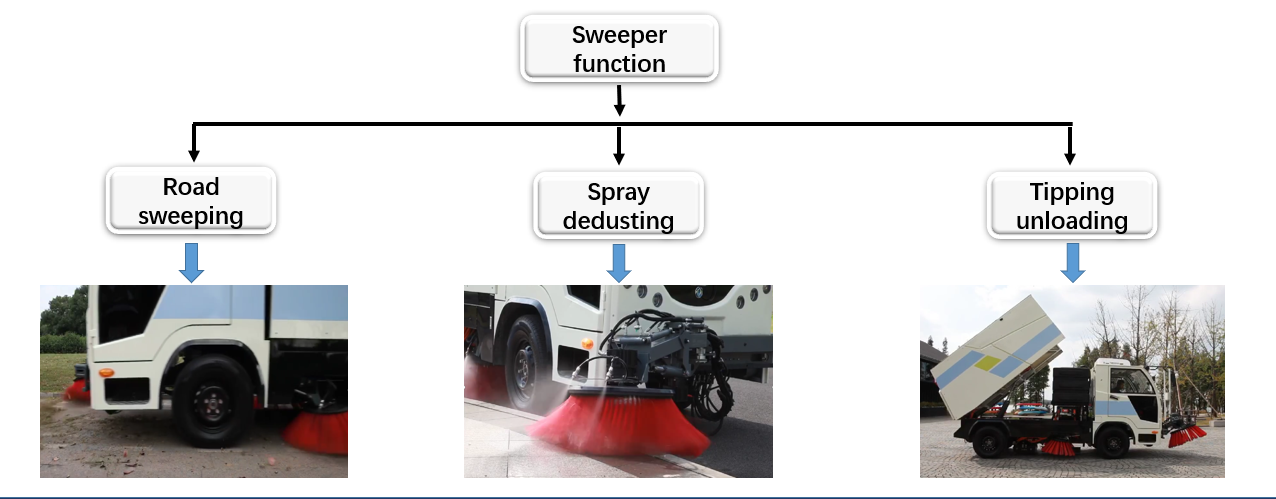

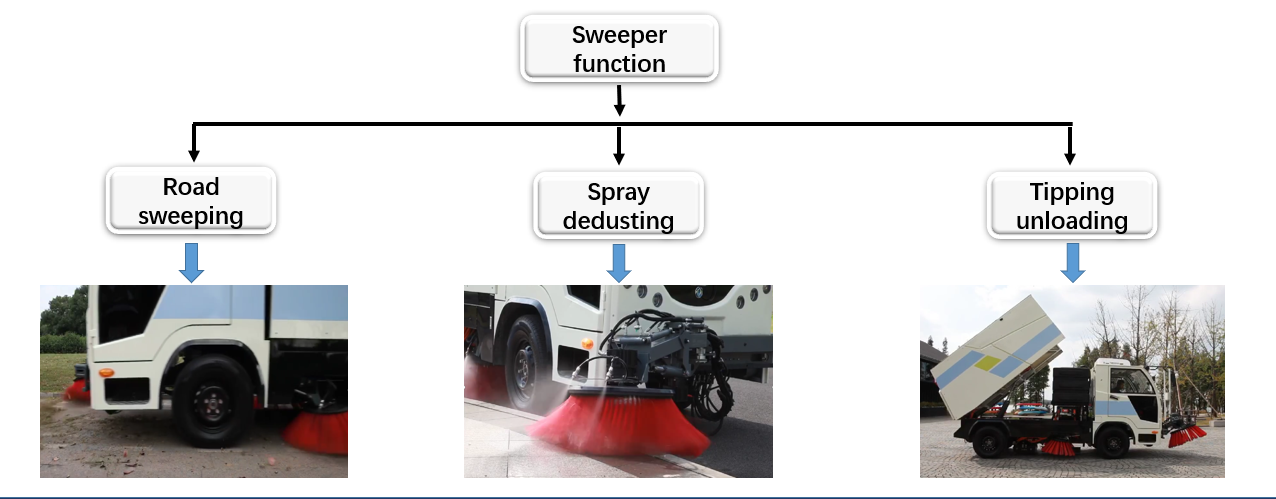

XML5050TSLJEVP0 pure electric road sweeper is a pure electric wet road sweeper developed and produced by our company in response to the national environmental protection initiative to realize the blue sky plan and avoid re pollution while cleaning the road. It is refitted with a pure electric chassis, which is equipped with a cleaning system consisting of a brush and a suction nozzle, a fan, a dustbin, a clean water tank, a dust reduction system, a hydraulic system and an electric control system. During the cleaning operation, the garbage collection is completed by means of disc permanent magnet synchronous motor direct drive high-pressure centrifugal fan operation, brush folding, suction nozzle negative pressure suction, water spray dust suppression and box filtration and sedimentation, so as to ensure the cleanness of the road and maintain the sanitation of the environment.

Structural Composition

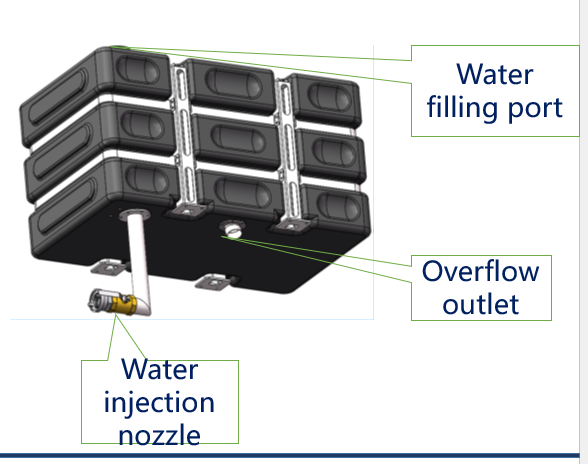

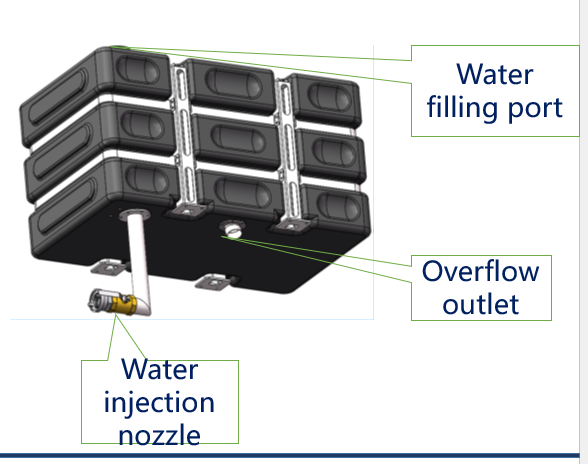

Clean Water Tank

The clean water tank is integrally molded with rubber, and the volume of the tank is 1m ³, It is composed of water injection port, cleaning port and overflow port.

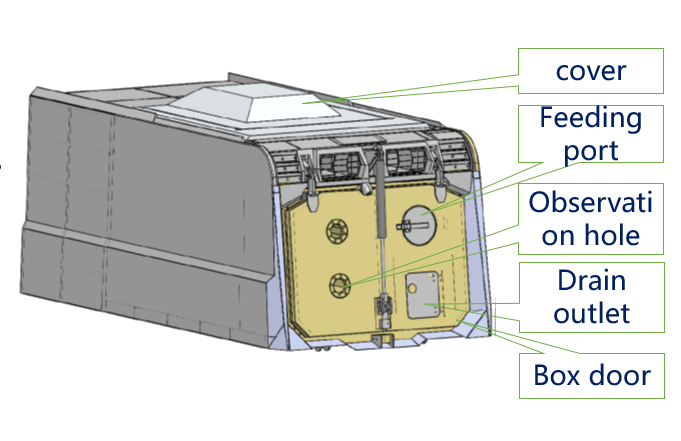

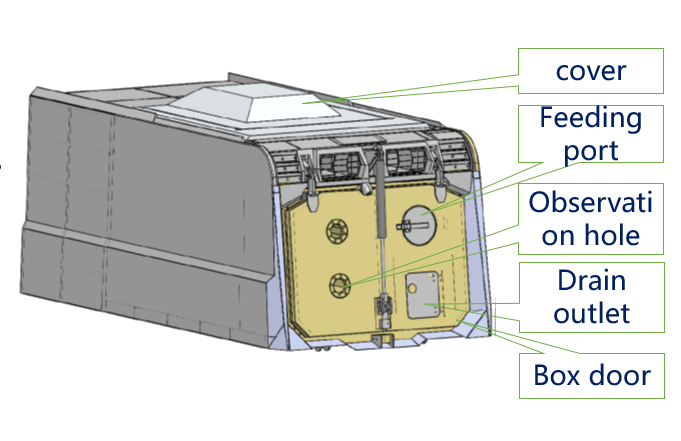

Dustbin

The garbage can is tipped and unloaded by the tipper cylinder. The volume of garbage can is 2.4m ³, It is a closed structure, which is used to collect, dump garbage and discharge sewage

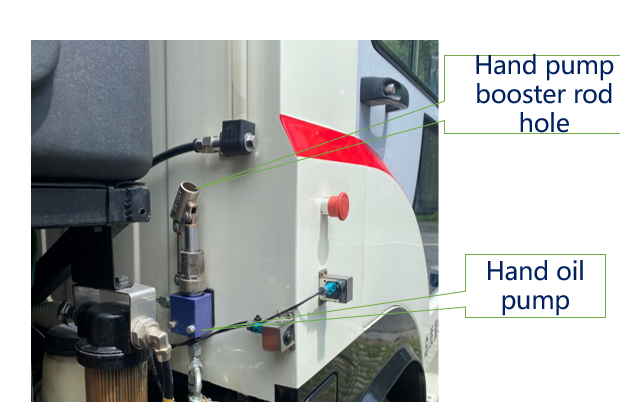

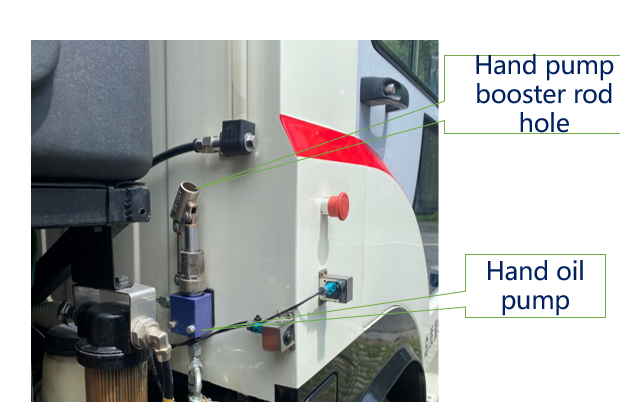

Hand Oil Pump

The hand pump is installed under the clean water tank, and the purpose of lifting the tank is achieved through the reciprocating action of the handle.When the hydraulic oil pump cannot work for some reason, use the hand-operated oil pump to jack up the garbage can for unloading or carry out maintenance operations. After the maintenance is completed, continue the follow-up operations, take back the lowered suction nozzle, the lowered sweeping plate, and open the back door of the garbage can.Operation method:

a. Park the road sweeper in a position suitable for unloading or maintenance operations, and place the parking brake handle in the "Parking" position.

b. Tighten the discharge valve of the hand pump, operate the handle of the hand pump, lift the garbage can in place, and support the safety support frame for convenient maintenance.

c. After the maintenance, take back the support safety frame, loosen the discharge valve of the hand pump, and operate other operations after the garbage can falls back in place.

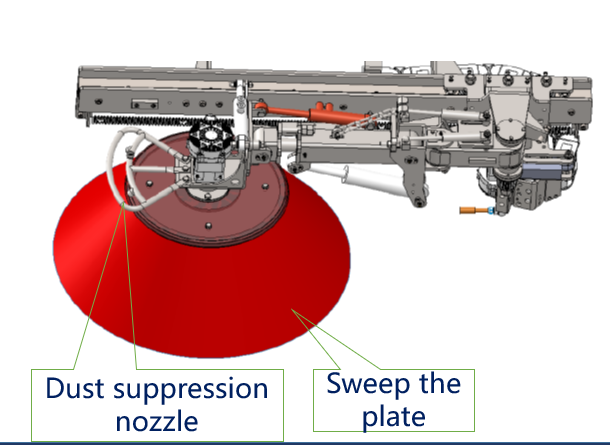

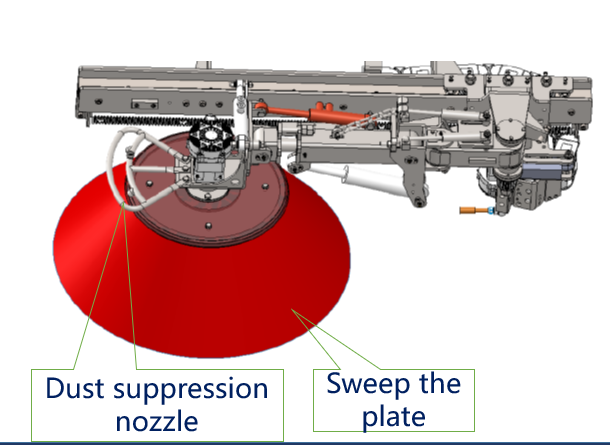

Sweeper

The sweeping device consists of three sweeping plates at the front, left and right. The maximum sweeping width is 2.5m, and the side structure is completely symmetrical. The sweeping plate is installed on the chassis, and the camber can be adjusted by using the forward tilt adjusting screw and the camber adjusting bolt.

To achieve the best cleaning effect, the working posture of the sweeping plate should be adjusted to make the contact state between the sweeping plate and the ground meet the requirements. The best effect can be guaranteed through three adjustments:

a. Adjustment of the rake angle of the sweeping plate: adjust the length of the rake adjusting rod (or oil cylinder), tilt the sweeping axis forward by 4-6 °, and lock it after adjustment.

b. Adjustment of the camber angle of the sweeping disc: when sweeping the left or right side, adjust the angle of the camber cylinder so that the sweeping disc is outward respectively. The left sweeping disc is tilted to the left and the right sweeping disc is tilted to the right by 4-6 °. Tighten the bolts after adjustment.

c. Adjustment of sweeping grounding force: the sweeping grounding force has been adjusted when leaving the factory, and there is no need to adjust it if there is no abnormality.

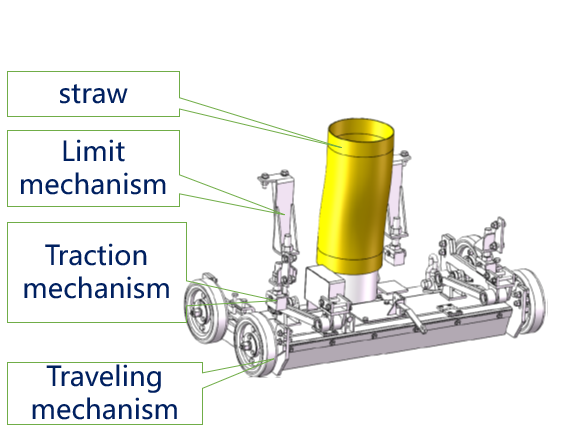

Suction Nozzle

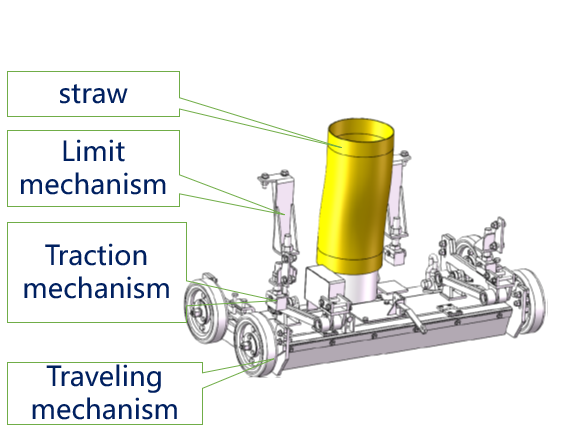

The suction nozzle is composed of straw, lifting mechanism, traction mechanism, limit mechanism, side roller, rubber plate, etc. When reversing and long-distance transportation, the suction nozzle needs to be lifted, positioned and fixed first. During operation, the suction nozzle needs to be put down, all walking wheels are on the ground, and the traction mechanism is responsible for traction. The suction port of this road sweeper is round, with a total diameter of 200mm.

In order to ensure the effect of dirt absorption and water absorption, the height from the ground of the rigid parts on both sides of the suction nozzle should be accurately adjusted after landing, and should be checked frequently.

a. Adjust the height adjustment mechanism on the walking wheel to ensure that the gap between the rigid parts on both sides and the road surface is about 5-10mm. The front and rear ends of the suction nozzle body are equipped with sealing rubber plates, which should be replaced in time after wear.

b. When not cleaning, lift the suction nozzle through the lifting device to ensure that the ground clearance of the rigid part of the suction nozzle is greater than 130mm for fast driving.

Basic Parameters | Vehicle Size (MM) | 5500,5630×1740×2415,2330 | Maximum Climbing Gradient | ≥20% |

Maximum Total Mass/Curb Weight (KG) | 5000/4560 | Minimum Turning Diameter (M) | 10 |

Maximum Speed (KM/H) | 80 | Driving Range (KM) | 380(Isokinetic method) |

Power configuration | Chassis Model | EQ1050TACEV | Peak Power/Speed Torque Of Drive Motor | 120kW/9000RPM/420N•M |

Power Battery | CATL Lithium Iron Phosphate /105.28KWH | Controller | Heavy Truck Controller/Hub Motor Controller |

Drive Motor | Disk Hub Permanent Magnet Synchronous Motor / TZ260XS120 | | |

Chassis configuration | Axle/Suspension System | Front Independent Suspension/Rear Leaf Spring Suspension Rigid Axle/Direct Drive | Steering System | Hydraulic Power Assisted/Recirculating Ball Steering Gear |

braking System | Dual Circuit Hydraulic Brake/Hydraulic Power Assist /Self Reinforcing Drum Parking Brake / Automatic Brake Clearance Adjustment /Abs | Air Conditioning Heating System | Air Conditioner |

Tyre | 205/75R17.5 14PR | | |

Electrical Equipment Configuration | Monitoring System | Reverse Image+Operation Monitoring | Other | LCD Meter, Water Level Alarm, Music Horn, Warning Light, Pressure Gauge |

Cab Accessories | USB Charging Port, Cup Holder, Storage Box | | |

Upper Configuration | Volume Of Water Tank/Garbage Can (M) | 1.0/2.0 | Operation Control | Loading One Key Operation Mode; Economic/Standard/Enhanced Three Cleaning |

Fan/Motor | High Voltage Centrifugal Fan/Disc Hub Permanent Magnet Synchronous Motor | other | Constant Speed Cruise (Only In Operation Mode) |

Brush | Front Dual Brush+Middle Dual Brush/Disk Hub Permanent Magnet Synchronous Motor Drive/With Spring Adaptive Function | Operation time (H) | ≥12 |

Sweeping Width (M) | 2.5 | | |

English

English

English

English Français

Français Deutsch

Deutsch Pусский

Pусский Español

Español العربية

العربية ไทย

ไทย עברית

עברית 中文

中文 Português

Português

IPv6 network supported

IPv6 network supported